Do You Have an Appetite for Being a Risk-taker?

How about Building Deep-Tech Start-Ups?

Kallol Roy (1984)

To the gen-next—those in College or those who would have completed a few years back—Consider a Start-up Eco-System which may re-shape our industrial landscape—evolving think-tanks to offer multifarious consultancy services, tying up academic excellence to industrial outcomes, bridging the gaps in supply chain for critical infra industries—be a leader in technology driving, techno-commercial innovations, creating sustainable business models, and what have you ??

Part-1 Evolving think-tanks to offer multifarious consultancy services: Harnessing Industrial Transitioning Models and Linking the same with Societal Transitioning Aspects Become a Consultant in the Micro Small & Medium Enterprises (MSME) Segment

Ideations from Industry-4.0

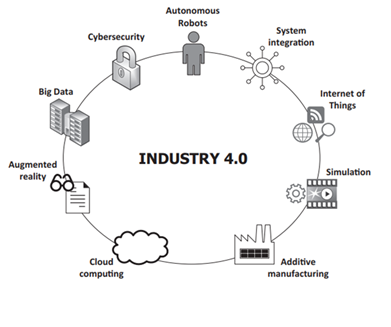

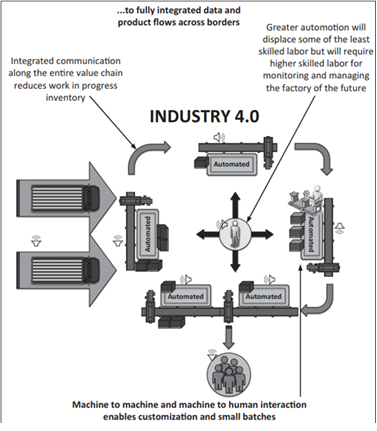

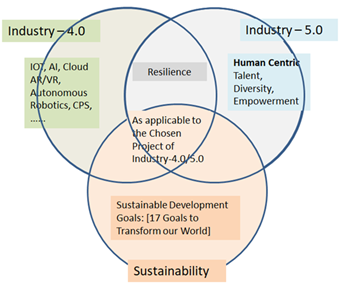

Out of the many paradigms helping in re-shaping the start-up perceptions during the past decade one has been the framework of Indusry-4.0, with its all-encompassing umbrella of disruptive technologies, which have grown and matured over the past two decades, viz. Internet of Things (IoT), Cloud Computing, Additive Manufacturing (3D Printing), Virtual Reality (VR) & Augmented Reality (AR), Digital Twins, etc. Since Industry-4.0 essentially focused on digitalization, automation, and communication, it enables faster, flexible, efficient, and high-quality low-cost processing in the industries. Thus it has envisaged machines to be capable of interacting with the plant operator, system & equipment designer, quality engineer, etc. and even with other machines. Further, such machines were designed to have the capability of self-learning by collecting real-time data and storage from the cloud.

Connectivity has also been one of the important aspects of Industry 4.0, intended for improving collaboration & coordinated functioning across various industrial segments in a plant, viz. operating island, shop-floors, maintenance bays, etc. along with the human operators/maintainers/designers, etc.

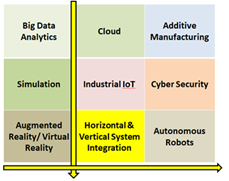

Thus the perspective of Industry 4.0 has been to offer high flexibility, self-optimization, self-configuration, self-diagnosis, cognition, and intelligent support at different levels. In critical infrastructure industry, it was meant to provide the advantages of quick response to change in demand, faster innovations, customized production, decentralized production, less errors/defects, and low-cost operation/production. Further, a concept of Horizontal & Vertical System Integration, across the various technologies, as indicated in the figure below, extends the connectivity concepts of Industry-4.0 paradigm.

A. A few start-ups which you may consider in MSME Space, in the framework of Industry-4.0

(a) Evolving Expertise in Augmented Reality (AR) & Virtual Reality (VR) Tools, and Offering It as a Service

The basic approach of getting an individual worker to carry out an apriori virtual practice-session/rehearsal of a critical job, with its associated risks (viz. working below construction equipment, working at heights, working inside caissons, working in confined spaces along with complex machinery, etc.), has an inherent advantage of offering a combined training to an individual, in a simulated VR/AR environment, along with an improved perception of the necessary safety procedures & practices. Such VR/AR models of various Systems, Structures & Equipment (SSE) not only provide opportunities to an individual to understand the JHA & HAZOP flow-sheets of a critical job, but also to work around the plant-safety and industrial-safety issues.

Thus, developing accurate Virtual Reality (VR)/Augmented Reality (AR) models of various SSEs could be built-in to the various procedures, to sensitize & train individuals, prior to undertaking critical jobs on SSEs, pertaining to construction activity at heights and in closed spaces, erection and mounting of large equipment, commissioning of systems, precision repair and rectification of specific SSEs, operations and in-situ maintenance of process and roto-dynamic equipment. Such procedures, which factor in traditional theoretical training methods along with virtual hands-on training, are expected to significantly improve the Human Reliability figure-of-merit. Further, helping intelligent decision-making during a simulated training/learning exercise, would also provide a formal framework towards reduction of human errors and add to the safety in job executions.

(b) Partnering with the Alma Mater to plan a consultancy concept for working across multiple MSMEs and enabling a Horizontal & Vertical System Integration concept in the framework of a hub and spoke model. Here an incubation space/lab in the College acts as the centralized main hub (having the design/experimental/computational facilities or set-ups) for connecting to the various spokes (MSMEs/Start-ups on big-data analytics, AR/VR, 3D printing, autonomous controls/robotics, etc.) which act as the peripheral points that do not connect directly to each other. On similar lines to such a model used in logistics, airlines, and network infrastructure to centralize operations, (wherein cost and efficiency is improved through channeling goods, passengers, or data through a central point before they are dispersed to their final destinations), here you may consider the hub as a technology experimenter/developer and the spokes as centers for technology commercialization and routing.

B. Furthering Ideations through Industry-5.0

(a) With the subsequent push towards more societal & personalized approaches for various engineering paradigms, the concepts & tools of Industry-4.0 are, in recent years, giving way to a newer growth-engine of Industry-5.0. This framework has a major shift in focus towards a coordinated growth of Cyber Physical Systems (CPS) along with the societal eco-system (essentially Society-5.0). It foresees a customized & personalized CPS structure in close coordination with the human and thereby is all about aiding & enhancing the human performance—be it in manufacturing, plant operations, transportation, healthcare, etc., all in a framework of collaborative & hyper-customized societal & industrial eco-system.

(b) Customizing AI/ML Tools as an Industrial Support: Advanced AI/ML tools incorporated in CPS form a major part of this endeavor, wherein humans along with their CPS tools, together form an integrated environment for providing the industrial, techno-commercial & socio-economic thrust. Since such a cyber-physical eco-system is a combination of AI/ML along with the supervisory control of the human mind, the total safety culture is a product of supervisory training and the quality assurance of the CPS.

(c) Consultants in Industry-5.0 Adaptation: Industry 5.0 introduces the potential for sustainability improvements. By placing humans at the center of manufacturing processes, it can lead to more responsible decision-making regarding environmental impact and social consequences.

Human involvement in complex tasks can enable better judgment in ethical and sustainability-related issues. This is a systematic process of industrial up-cycling for prevention of wastage (this phenomenon was witnessed during the first phase of industrial revolution, where humans were ignored and mechanization was preferred). Later during the human-relation era of management, it was realized that humans have equal significance as machines in a manufacturing process. Similarly, during the introduction of AI under Industry-4.0, human capabilities were progressively being ignored, resulting in a need to shift to Industry-5.0 to make a perfect collaboration between human and AI.

(d) Consultants for Transitioning to Industry-5.0: Transitioning to Industry-5.0 poses its own set of challenges. The focus should be on designing systems that ensure the well-being of workers in this new environment, balancing automation with human needs. Moreover, the environmental impact of technological advancements should remain a central concern for the implementation in Industry-5.0. While Industry-4.0 laid the groundwork for increased efficiency, Industry-5.0 envisions a future where technology complements human skills to drive sustainability. This transition, if managed responsibly, has the potential to align industrial progress with environmental and social goals.

Conclusion

The MSME segment is India’s backbone, accounting for a significant portion of our GDP and employing millions. Yet, most MSMEs lack the in-house expertise to absorb the rapid transitions in industrial technology. Consultants can therefore:

- Bridge the gap between cutting-edge academic research and shop-floor application

- Provide affordable, scalable, and customized solutions

- Create sustainable techno-commercial models tailored for smaller enterprises

- Ensure MSMEs remain globally competitive while meeting local societal needs

The consultancy ecosystem itself is evolving, from specialized think-tanks to multifarious service providers bridging industry and society. For young engineers, this presents an unprecedented opportunity: to be not just job-seekers but solution architects in the MSME sector.

By harnessing the transitioning models of Industry 4.0 and Industry 5.0, and linking them with societal needs, tomorrow’s consultants can drive industrial progress that is sustainable, inclusive, and human-centric.

************************************************