Part I of this article was published in Volume 1 of Kattangal Chimes, dt. October 2025.

Read it here: https://kattangalchimes.in/ind-5-0-a-start-up-roadmap-kallol-roy/

Kallol Roy (1984)

Reaching out to our gen-next once again—for those in College or those who would have completed a few years back—consider deep-tech start-ups in core-engineering—those which will offer solutions for both industrial and societal eco-system which may address some of the aspects of both Industry 4.0 and 5.0 and re-shape our lifestyle and the ways in which we would make a living—and as before, you should be a leader in pushing the boundaries of Industry 5.0 and create sustainable deep-tech business models, while adhering to the UN SDGs.

____________________________________________________________________________________________________

Part-2 Applying available core engineering knowledge along with upcoming research areas in academia, to develop applications in advanced robotic domains, developing high-end exoskeletons for enhancing industrial safety and offering “cobot” solutions, for coordinated efforts in the shop-floor and distributing works in hazardous process-plant environments

_____________________________________________________________________________________________________

1.0 Enabling the Consultancy Start-up Teams to Join Hands with the Deep-Tech Founders Starting from where we left off in our earlier article, let us reiterate that while we have a vision for deep-tech start-ups, the focus should continue to remain on designing systems that ensure the well-being of workers in this new industrial environment, balancing automation with human needs, and creating the foundations for incorporation of AI/ML tools. Towards this, we should continue to further our resolves in what we concluded earlier, and consciously focus on design, development & building systems, as a coordinated team of multi-disciplinary expert start-ups, thereby reiterating our earlier aspirations to :

- Bridge the gap between cutting-edge academic research and shop-floor applications;

- Provide affordable, scalable, and customized solutions;

- Create sustainable techno-commercial models tailored for smaller enterprises;

- Ensure that the start-ups of today become large enterprises of tomorrow and remain globally competitive while meeting local societal needs.

Again, taking forward our earlier discussions, the environmental impact of technological advancements should remain a central concern and live up to the paradigms of Industry-5.0, which envisions a future where technology complements human skills to drive sustainability and aligns industrial progress with environmental and social goals. [1]

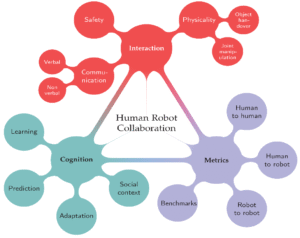

2.0 Hallmark of Industry-5.0 — All about being “Human-Centric”, being “Resilient” and being “Sustainable”

A shift is needed to a human-centric focus, wherein human-needs are placed at the forefront of the production process, and which integrates value-driven, human-centric initiatives with the technological advancements of the earlier Industry 4.0, thereby creating a more harmonious interaction between humans and machines.

Fig.1 : Reconstructed from [1,2,3]

Further, in a resilient industry, production processes exhibit high robustness, safeguarding against disruptions and supporting critical infrastructure during crises. Also, by creating a sustainable industry by businesses adopting circular economy processes, to minimize environmental impact, all the three vertices of Industry 5.0 are achieved. [2,3]

Some of the key enablers of technology advancements in this space, which have a dual leaning to both society and industry, are presented here: “hopping robots” for performing effective rescue operations as a part of disaster management; “exoskeletons” as an industrial safety concept for helping individuals with load movements in construction sites; the “falling cat problem” as a computational tool built on the exoskeleton to minimize the risks of individual workers in falling from heights; and “coordinated humans & advanced robots” (cobots) of multiple types for job distributions in hazardous industrial environments. In my opinion, these suggested technologies can be built easily with existing resources (intellectual, technological, and precision manufacture) and also have strong innovation component both for industrial and societal usage.

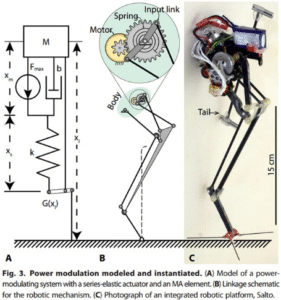

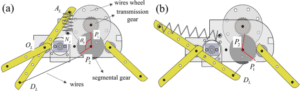

3.0 Building a Start-up for Design, Development, Fabrication, & Customizing

(a) Hopping Robots: This is essentially a bio-inspired technology which visualizes an animal hopping from one unstable surface (branch of a tree) and landing on another, without losing its own stability or grip. “A hopping robot uses a spring-like mechanism or other propulsion to leap over obstacles, offering an energy-efficient way to navigate complex terrains like disaster zones (or planetary surfaces), combining aspects of crawling and flying robots for agility. Developments feature tiny, winged bots that can jump multiple times their height for exploration. These robots can use energy recycling (like pogo sticks) for efficiency, rely on flapping wings for control, and are being developed for tasks from search & rescue to exploring icy moons”. (italicized para in quotes, taken from an AI tool, for ease of standardization).

For a start-up with indigenously available resources, a hopping robot can be conceived to serve multiple purposes, and a general approach for their design could be based on spring-assisted multi-link mechanisms or even drone-assisted mechanisms having a set of miniaturized multi-link mechanisms with gear-trains for many degrees of freedom and variable torques. Needless to say, this requires a deep knowledge of theory of multi-link mechanism designs, CAM-based designs, multi-body dynamics, FEM-based analysis of stress points, aerodynamic models & associated CFD models, etc. Perhaps it may be a good idea to team up as a group of applied & computational mechanics geeks along with a team of math geeks.

A large number of designs and also prototype products are available, essentially developed by many student start-ups across the world. Theoretical discussions and many publications are also available in open domain, which could well serve as ideations, for consideration by many of you, which can then become patented indigenous products.

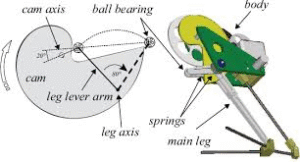

A few ideas of hopping-robot designs, as available in open literature, are shown below—these are purely for ideation and do not provide a detailed design concept. In addition, among others, you may choose to read [4–7] referred here and of course take a deep-dive into both academic literature and technological descriptors available in open domain.

Fig.2a

Fig.2b : (Acknowledgment : The pictures above (Fig.2a & Fig.2b) are representative & obtained from public domain, for ideation only.)

Fig.2c : (Acknowledgment : “Spring-linkage integrated mechanism design for jumping robots”, Xuan Chun, et al, Robotics & Autonomous Systems, Volume 158, December 2022, 104268)

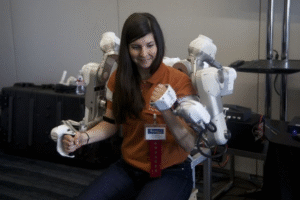

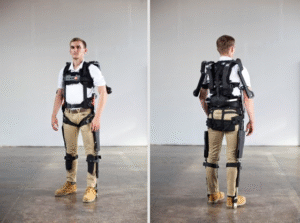

(b) Exoskeletons : “Exoskeletons are external mechanical frames, either natural (like insect shells) or artificial (wearable suits), that support, protect, and enhance the body’s strength, mobility, and endurance, used in rehabilitation, industry, and military for tasks from heavy lifting to walking assistance. Natural exoskeletons, made of chitin, provide armor for invertebrates but require molting to grow. Robotic exoskeletons use motors, AI, and sensors to amplify human movement, aiding recovery from paralysis or reducing strain in demanding jobs, offering features like power boosts and intelligent mode switching.” (italicized paragraph in quotes is taken from an AI tool, for ease of standardization).

Fig.3 : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideation only)

Fig.3 : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideation only)

“This field uses principles from biomechanics and robotics to understand and optimize the human-machine interaction” (sentence taken from AI tool). Kinematics of exoskeletons studies their motion, design, and alignment with human joints, focusing on Degrees of Freedom (DOFs), joint matching, and mobility restrictions to ensure effective assistance without hindering natural movement, often using forward/inverse kinematics models for design, simulation and gait analysis to minimize misalignment and improve human-exoskeleton synchronization.

For obtaining further details on analysis and design of exoskeletons, it would be a good idea to take a deep dive into academic literature [8–12] referred here. In addition there are many other references, available as blogs, web-pages, etc. from organizations, universities, etc.

(c) Falling Cats : The falling-cat problem consists of explaining the underlying physics behind the cat’s righting reflex. Although amusing and trivial to pose, the solution of the problem is not as straightforward as its statement would suggest. The apparent contradiction with the law of conservation of angular momentum is resolved because the cat is not a rigid body, but instead is permitted to change its shape during the fall owing to its flexible backbone and non-functional collar-bone [4]. The behaviour of the cat is thus typical of the mechanics of deformable bodies.

Fig.4 : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideation only)

We can model the simplified “cat” as two cylinders connected by a flexible spine in the middle. We also assume that the flexible spine disallows twisting, so both cylinders can only rotate by the same degree. Thus, the configuration space of the system has only three dimensions:

- The overall angle of the cat around the horizontal axis.

- The bending angle of the spine

- The turning angle of the cylinders

Fig.5 : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideation only). Please use this link for a dynamic picture above : https://en.wikipedia.org/wiki/File:Cat_fall_150x300_6fps.gif

Framed this way, the dynamics of the falling cat problem is a prototypical example of a non-holonomic system, the study of which is among the central preoccupations of control theory. “A solution of the falling cat problem is a curve in the configuration space that is horizontal with respect to the connection (that is, it is admissible by the physics) with prescribed initial and final configurations. Finding an optimal solution is an example of optimal motion planning.” (sentence taken from Wikipedia, for standardized definition).

Rather than working with the study of the physics & m aths of the falling-cat problem, as a start-up, it may be worthwhile to consider incorporating this algorithm in the design of exoskeleton. This involves research in robotics and biomechanics that applies the physics principles of how a freely falling cat reorients itself to the design and control of self-righting or balance-correcting mechanism of an exoskeleton. This may be a big contribution towards industrial safety, for personnel working at heights. In the event of a fall (despite the safety gears for workers at height), which could otherwise have a fatal consequence, here the falling-cat algorithm, ensures that the worker falls on his/her legs, which effectively minimizes the trauma.

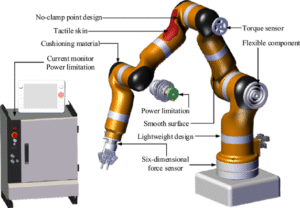

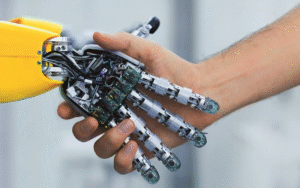

(d) Cobot : A cobot, or collaborative robot, also known as a companion robot, is a robot intended for direct human–robot interaction within a shared space, or where humans and robots work close together.

Fig.6 : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideation only)

Fig.6 : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideation only)

(i) Cobot applications contrast with traditional industrial robot applications in which robots are isolated from human contact or the humans are protected by robotic tech vests (which are special wearable equipment protecting workers near industrial robots—similar to a high-visibility jacket, wherein robots can sense a vest from a distance and avoid moving into it, thus protecting the wearer from collisions). Cobot safety may rely on lightweight construction materials, rounded edges, and inherent limitation of speed and force, or on sensors and software that ensure safe behavior. These robots are equipped with advanced sensors, software, and technology that allow them to adapt to variable environments, learn from humans, and perform tasks with precision and accuracy. They are designed with safety in mind and are capable of stopping or slowing down when a human is in close proximity, significantly reducing the chances of workplace injuries. [14–16]

Building a start-up in this area would of course require math geeks in the team to work through the subjects of “Calculus of Manifolds”, “Sub-Riemannian Geometry”, “Holonomic and Non-Holonomic Systems”, etc. with the other members in the team having a strong favour for “multi-link mechanisms”, “multi-body dynamics”, “co-operative controls”, etc.

Fig.7a : ( Acknowledgment : The pictures above are representative & obtained from public domain, for ideation only)

An experimental lab, for validating various designs may also be required for setting up such a start-up —optionally there could be a collaborative set of start-ups, with one providing a math consultancy, one providing the cobot design concepts both at system level & at component level, and a third offering consultancy in cooperative controls and reconfigurable controls. [16]

Fig.7b : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideation only)

Fig.7c : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideations only)

Fig.7c : (Acknowledgment : The pictures above are representative & obtained from public domain, for ideations only)

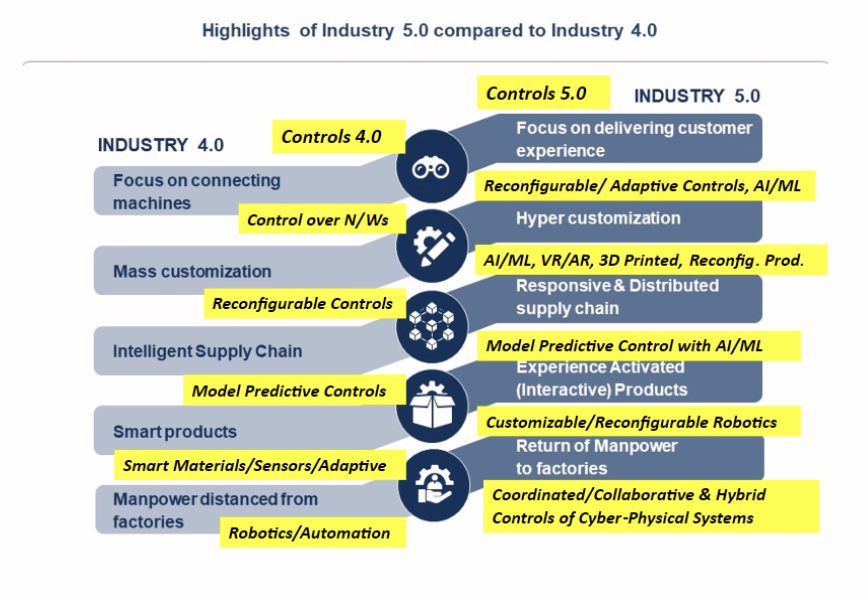

(ii) The figure below indicates the highlights of Industry 5.0 compared to Industry 4.0 and the titles superimposed on it (highlighted) show the corresponding control concepts – Control 5.0, which could be under the overall framework of Industry 5.0 for evolving such a multi-disciplinary start-up.

Fig.8 : (Acknowledgment : The base picture above is representative & obtained from public domain, for ideation only. The superimposed titles, pertaining to Controls 5.0, are by the author).

Fig.8 : (Acknowledgment : The base picture above is representative & obtained from public domain, for ideation only. The superimposed titles, pertaining to Controls 5.0, are by the author).

As can be seen, the aspects of Customizable/Reconfigurable Robotics and Coordinated/Collaborative & Hybrid Controls of Cyber-Physical Systems set the goals for various start-ups in the field of robotics & exoskeletons and pave the way for high-end research in cyber–physical coordinated functions and its benefits in both societal and industrial applications.

4.0 Using AI Tools on Top of the General–Purpose Robotic Devices

In order to incorporate the aspects of Customizable/Reconfigurable Robotics and Coordinated/Collaborative & Hybrid Controls of Cyber–Physical Systems it may be a good idea to also consider building a computational solver (for carrying out many of the deterministic computational problems) over a hopping robot or an exoskeleton or for any type of cobot performance, for periodic evaluation/ forecasting/ prognosis w.r.t. trajectory corrections, along with appropriate AI/ML tools, for necessary decision-making w.r.t. the next step (as required in a given scenario).

Fig.9 : (Acknowledgment : The picture above is representative & obtained from public domain, for ideation only)

Fig.9 : (Acknowledgment : The picture above is representative & obtained from public domain, for ideation only)

In this environment, simple deterministic algorithms run “if-then-else-if—” scenarios before computing/optimizing the next step/trajectory, before adjusting equipment set-points, while the AI tools would do decision-making and also diagnose complex upsets. [7,8] Thus, as a building block for Cobots, it may be a useful idea to also work towards building a cooperative controls strategy which harnesses the power of both algorithmic concepts for estimation/prediction/computation, etc. at every step and AI tools to evaluate the correctness of the algorithmic solutions generated, thereby creating a superior performing machine. [16,17]

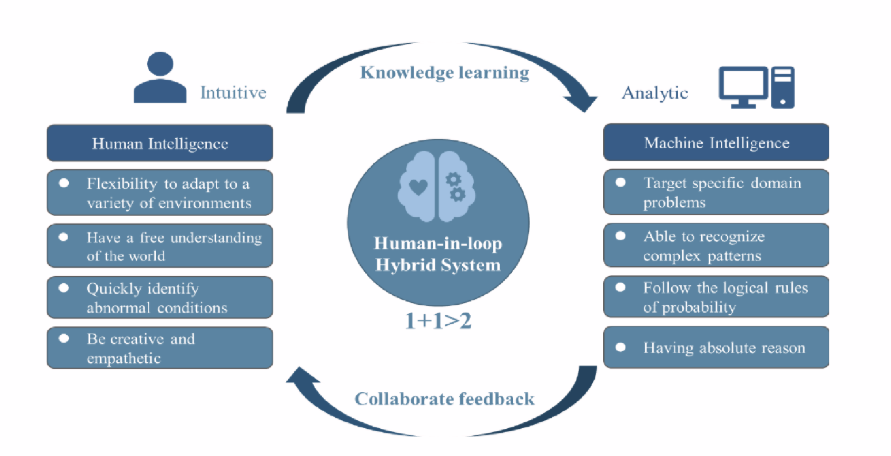

As a graded approach, however, one can initially consider a “human-in-loop” solution, which offers additional intuitive reasoning on AI-based decisions, and thereby strengthens the correctness of the outcome of the AI/ML tools. As the confidence of the AI/ML learnings increase, the “human-in-loop” configurations could be phased out. [18]

Fig.10 : (Acknowledgment : The pictures above are from [16,17])

The initial incorporation of an “human-in-loop” solution, apart from increasing the robustness of the cobot, also builds in necessary ethics in the AI tools and also addresses bias and hallucinations.

Conclusion

Reiterating the emphasis in the conclusion of the part I of this article, it may be further emphasized that by harnessing the transitioning models of Industry 4.0 and Industry 5.0, and linking them with societal needs, the deep-tech start-ups can offer solutions & products that are human-centric, resilient & sustainable and live up to the requirements of the UN SDGs. It may not be possible for a single group of experts to take the lead for all the suggested areas, but could very well be a team effort for building a consortium.

References

- Deepak Verma “Industry 5.0: A Human-Centric and Sustainable Approach to Industrial Development” in International Journal of Social Relevance & Concern (IJSRC) ISSN:2347-9698, ijournals.in/ijsrc, Volume 12, Issue 5, May 2024

- Carolina Feliciana Machado and João Paulo Davim (Editors) Industry 5.0 Creative and Innovative Organizations, Springer, ISBN 978-3-031-26231-9 2023; João Paulo Davim, Department of Mechanical Engineering, University of Aveiro, Portugal ISBN 978-3-031-26232-6 (eBook) https://doi.org/10.1007/978-3-031-26232-6

- Marko MLADINEO, et al. “Human Centric Approach of the Lean Management as an Enabler of Industry-5.0 in SMEs” at International Conference of Mechanical Technologies and Structural Materials Split 23-24 09, 2021

- S.H.Hyon, et al. “Development of a Biologically Inspired Hopping Robot – ‘Kenken’” in Proceedings of the 2002 IEEE International Conference on Robotics 8 Automation, Washington DC, May 2002

- Jixue Mo et al. “Design and Locomotion Characteristic Analysis of Two Kinds of Tensegrity Hopping Robots” in iScience, Open Access

- “Hopping Robots to Traverse Challenging Terrain” in Tech Briefs (in public domain)

- Martin Biihler “Analysis of a Simplified Hopping Robot”, Center for Systems Science, Yale University, Department of Electrical Engineering 1988

- Yang Z et al. “Force Control of Exoskeleton Suit Based on Inner Position Loop” in Force Control Theory and Method of Human Load Carrying Exoskeleton Suit Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-54144-9_5

- Klaus Bengler et al. “Exoskeletons: A challenge for development” in Wearable Technologies (2023), 4, e1 doi:10.1017/wtc.2022.28, Review Article, Cambridge University Press

- Han Ali et al. “Kinematic Analysis of Lower Extremity Exoskeleton” at Chinese Control and Decision Conference (CCDC 2008), School of Mechanical Engg., Nanjing

- Elisa Panero et al. “Kinematic Effects of a Back-Assistance Exoskeleton During Human Locomotion” in Applied Ergonomics 126 (2025) 104502

- Jacob Segil Handbook of Bio Mechanics ISBN : 978-0-12-812539-7, Elsevier Inc., 2009

- Yoshihisa Sakurai “Falling cat problem” Department of Mechanical and Aeronautical Engineering University of California, Davis, yosakurai@ucdavis.edu, June 9, 2009

- Sihan Huang et al. “Industry 5.0 and Society 5.0—Comparison, complementation and co-evolution” in Journal of Manufacturing Systems 64(2022)424-428

- “Symphony of Humans & Cobots” Blog in Public Domain 7

- “Revolutionizing Manufacturing: The Power of Human-Robot Collaboration” Presentation blog

- Zhenghao Liu et al. “Hybrid Intelligence in Big Data Environment: Concepts, Architectures, and Applications of Intelligent Service”, in Data and Information Management 5(2): 1–15 2021 (Open Access)

- Nan-ning ZHENG et al. “Hybrid-Augmented Intelligence: Collaboration and Cognition” in Frontiers of Information Technology & Electronic Engineering www.zju.edu.cn/jzus; engineering.cae.cn; www.springerlink.com, ISSN 2095-9184 (print); ISSN 2095-9230 (online)

For further discussion or information on this topic, the Author may be contacted through Kattangal Chimes. Please write to submissionsnitcaa@gmail.com.